Nikola Tesla Patents

Nikola Tesla British Patent 6481 - Improvements Relating to the Electrical Transmission of Power and to Apparatus Therefor

Date of Application, 1st May, 1888

Specification Accepted, 1st June, 1888

A.D. 1888, 1st May. No 6481.

COMPLETE SPECIFICATION.

[Communicated from abroad by Nikola Tesla, of the City and State of New York, United States of America, Electrician.]

Improvements Relating to the Electrical Transmission of Power and to Apparatus Therefor

I, Henry Harris Lake, of the firm of Haseltine, Lake & Co., Patent Agents Southampton Buildings, in the County of Middlesex, do hereby declare the nature of this invention and in what manner the same is to be performed, to be particularly described and ascertained in and by the following statement:-

The practical solution of the problem of the electrical conversion and transmission of mechanical energy involves certain requirements which the apparatus and systems heretofore employed have not been capable of fulfilling.

Such a solution primarily demands a uniformity of speed in the motor, irrespective of its load within its normal working limits. On the other hand, it is necessary to attain a greater economy of conversion than has heretofore existed, to construct cheaper, more reliable and simple apparatus, and such that all danger and disadvantages from the use of currents of high tension, which are necessary to an economical transmission, may be avoided.

This invention comprises a new method and apparatus for effecting the transmission of power by electrical agency whereby many of the present objections are overcome and great economy and efficiency secured.

In the practice of this invention a motor is employed in which there are two or more independent energizing circuits through which are passed, in the manner hereinafter described, alternating currents, which effect a progressive shifting of the magnetism or of the “lines of force” which, in accordance with well known theories, produces the action of the motor.

It is obvious that a proper progressive shifting or movement of the lines of force may be utilized to set up a movement or rotation of either element of the motor, the armature of the field magnet, and that if the currents directed through the several circuits of the motor are in the proper direction no commutator for the motor will be required. So, to avoid all the usual commutating appliances in the system, the motor circuits are connected directly with those of a suitable alternating current generator. The practical results of such a system, its economical advantages, and the mode of its construction and operation will be described more in detail by reference to the accompanying drawings and diagrams.

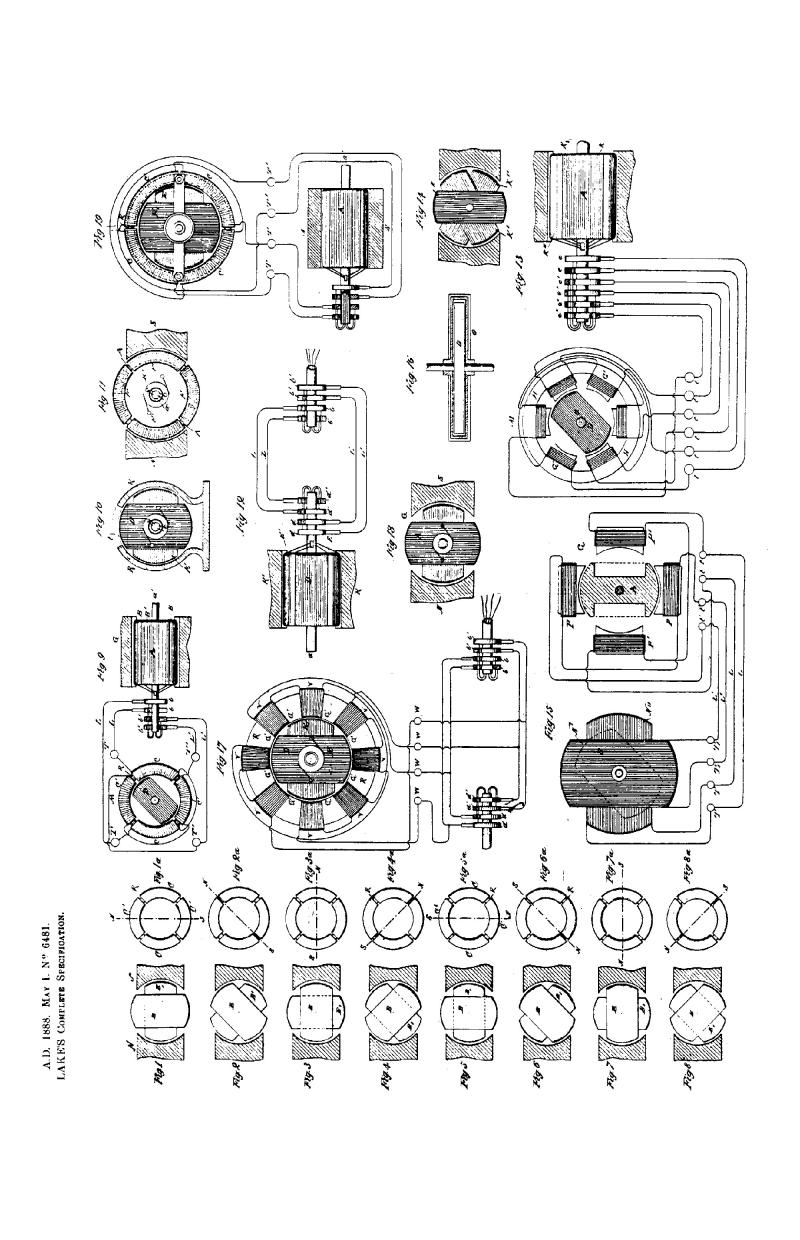

Figures 1 to 8 and 1a to 8a, inclusive, are diagrams illustrating the principle of the action of this invention. The remaining Figures are views of the apparatus in various forms by means of which the invention may be carried into effect and which will be described in their order.

Referring first to Figure 9, which is a diagramatic representation of a motor, a generator and connecting circuits in accordance with the invention, M is the motor and G the generator for driving it. The motor comprises a ring or annulus R, preferably built up of thin insulated iron rings or annular plates, so as to be as susceptible as possible to variations in its magnetic condition.

This ring is surrounded by four coils of insulated wire, symmetrically placed, and designated by C C C1 C1. The diametrically opposite coils are connected up so as co-operate in pairs in producing free poles on diametrically opposite parts of the ring. The four free ends thus left are connected to terminals T T T1 T1 as indicated.

Near the ring, and preferably inside of it, there is mounted on an axis or shaft a magnetic disk D generally circular is shape, but having two segments cut away as shown. This disk should turn freely within the ring R.

The generator G is of an ordinary type, that shown in the present instance having field magnets N S and a cylindrical armature core A, wound with the two coils B B1. The free ends of each coil are carried through the shaft a1 and connected respectively, to insulated contact rings b b b1 b1. Any convenient form of collector or brush bears on each ring and forms a terminal by which the current to and from the ring is conveyed. These terminals are connected to the terminals of the motor by the wires L and L1 in the manner indicated, whereby two complete circuits are formed, one including, say, the coils B of the generator and C1 C1 of the motor, and the other the remaining coils B1 and C C of the generator and the motor.

It remains now to explain the mode of operation of this system, and for this purpose reference is made to the diagrams Figures 1 to 8 and 1a to 8a for an illustration of the various phases through which the coils of the generator pass when in operation, and the corresponding and resultant magnetic changes produced in the motor.

The revolution of the armature of the generator between the field magnets N S obviously produces in the coils B B1 alternating currents the intensity and direction of which depend upon well known laws. In the position of the coils, indicated in Figure 1, the current in the coil B is practically nil, whereas the coil B1 at the same time is developing its maximum current, and by the means indicated in the description of Figure 9 the circuit including this coil may also include say, the coils C C of the motor, Figure 1a. The result, with the proper connections, would be the magnetization of the ring R, the poles being on the line N S.

The same order of connections being observed between the coil B and the coil C1 C1, the latter, when traversed by a current, tend to fix the poles at right angles to the line N S of Figure 1a. It results therefore, that when the generator coils have made one-eighth of a revolution, reaching the position shown in Figure 2, both pairs of coils C and C1 will be traversed by currents which act in opposition in so far as the location of the poles is concerned. The position of the poles will therefore be determined by the resultant effect of the magnetizing forces of the coils, that is to say, it will advance along the ring to a position corresponding to one-eighth of the revolution of the armature of the generator.

In Figure 3 the armature of the generator has progressed to one-fourth of a revolution. At the point indicated the current in the coil B is maximum while in B1 it is nil, the latter coil being in its neutral position. The poles of the ring R in Figure 3a will in consequence, be shifted to a position ninety degrees from that at the start as shown. The conditions existing at each successive eighth of one revolution are in like manner shown in the remaining Figures. A short reference to these Figures will suffice to an understanding of their significance. Figures 4 and 4a illustrate the conditions which exist when the generator armature has completed three-eighths of a revolution. Here both coils are generating current, but the coil B1 having now entered the opposite field is generating a current in the opposite direction, having the opposite magnetizing effect. Hence, the resultant poles will be on the line N S as shown.

In Figure 5 and 5a one half of one revolution has been completed with a corresponding movement of the polar line of the motor. In this phase coil B is in its neutral position while coil B1 is generating its maximum current; the current being in the same direction as in Figure 4.

In Figure 6 the armature has completed five-eighths of a revolution. In this position coil B1 develops a less powerful current, but in the same direction as before. The coil B on the other hand, having entered a field of opposite polarity, generates a current of opposite direction. The resultant poles will therefore be on the line N S Figure 6a, or in other words, the poles of the ring will be shifted along five-eighths of its periphery.

Figures 7 and 7a in the same manner illustrate the phases of the generator and ring at three quarters of a revolution, and Figures 8 and 8a those at seven-eighths of a revolution of the generator armature. These Figures will be readily understood from the foregoing.

When a complete revolution is accomplished, the conditions existing at the start are reestablished and the same action is repeated for the next and all subsequent revolutions, and in general, it will now be seen that every revolution of the armature of the generator produces a corresponding shifting of the poles or lines of force around the ring.

This effect is utilized to produce the rotation of a body or armature in a variety of ways. For example, applying the principle above described to the apparatus shown in Figure 9 ; the disk D owing to its tendency to assume that position in which it embraces the greatest possible number of magnetic lines, is set in rotation following the motion of the lines or the points of greatest attraction.

The disk D in Figure 9, is shown as cut away on opposite sides, but this will not be found essential to its operation ; as a circular disk, as indicated by dotted lines, would also be maintained in rotation. This phenomenon is probably attributable to a certain inertia or resistance inherent in the metal to the rapid shifting of the lines of force through the same, which results in a continuous tangential pull upon the disk that causes its rotation. This seems to be confirmed by the fact that a circular disk of steel is more effectively rotated than one of soft iron, for the reason that the former is assumed to possess a greater resistance to the shifting of the magnetic lines.

In illustration of other forms of apparatus by means of which this invention may be carried out reference is now made to the remaining figures of the drawings.

Figure 10 is a view in elevation and part vertical section of a motor. Figure 12 is a top view of the same with the field in section and exhibiting a diagram of the connections. Figure 11 is an end or side view of the generator with the fields in section. This form of motor may be used in place of that described.

D is a cylindrical or drum armature core, which for obvious reasons should be split up as far as practicable to prevent the circulation within it of currents of induction. The core is wound longitudinally with two coils E E1, the ends of which are respectively connected to insulated contact rings d d d1 d1 carried by the shaft a upon which the armature is mounted.

The armature is arranged to revolve within an iron shell R which constitutes the field magnet or other element of the motor. This shell is preferably formed with a slot or opening r, but it may be continuous as shown by the dotted lines, and in this event it is preferably made of steel. It is also desirable that this shell should be divided up similarly to the armature and for similar reasons.

The generator for driving this motor may be such as that shown in Figure 11. This represents an annular or ring armature A surrounded by four coils F F F1 F1 of which, those diametrically opposite are connected in series so that four free ends are left which are connected to the insulated contact rings b b b1 b1. The ring is mounted on a shaft a1 between the poles N S.

The contact rings of each pair of generator coils are connected to those of the motor respectively by means of contact brushes and the two pairs of conductors L L L1 L1, as indicated diagramatically in Figure 12.

It is obvious from a consideration of the preceding Figures that the rotation of the generator ring produces currents in the coils F F1 which, being transmitted to the motor coils, impart to the armature core of the motor, magnetic poles which are constantly shifted around the core. This effect sets up a rotation of the motor armature owing to the attractive force between the shell R and the poles of the armature, but inasmuch as the coils in this case move relatively to the shell or field magnets the movement of the coils is in the opposite direction to the progressive movement of poles.

Other arrangements of the coils of both generator and motor are possible and a greater number of circuits may be used as will be seen in the two succeeding Figures.

Figure 13 is a diagramatic illustration of a motor and a generator, connected and constructed in accordance with the invention. Figure 14 is an end view of the generator with its field magnets in section.

The field of the motor M is produced by six magnetic poles G1 G1 secured to or projecting from a ring or frame H. These magnets or poles are wound with insulated coils, those diametrically opposite to each other being connected in pairs so as to produce opposite poles in each pair. This leaves six free ends which are connected to the terminals.

The armature which is mounted to rotate between the poles is a cylinder or disk D of wrought iron, on the shaft a. Two segments of the disk are cut away as shown.

The generator for this motor has, in this instance, an armature A wound with three coils K K1 K11 at 60 degrees apart. The ends of these coils are connected respectively to insulated contact rings e e e1 e1 e11 e11. These rings are connected to those of the motor in proper order by means of collecting brushes and six wires forming the independent circuits. The variations in the strength and direction of the currents transmitted through these circuits and traversing the coils of the motor produce a steadily progressive shifting of the resultant attractive forces exerted by the poles G1 upon the armature D and consequently keep the armature in rapid rotation. The special advantage of this disposition is in obtaining a more concentrated and powerful field. The application of this principle to systems involving multiple circuits generally will be understood from this apparatus.

Referring now to Figures 15 and 16; Figure 15 is a diagramatic representation of a modified disposition of the invention. Figure 16 is a horizontal cross-section of the motor.

In this case a disk D, of magnetic metal, preferably cut away at opposite edges as shown in dotted lines in the Figure, is mounted so as to turn freely inside two stationary coils N1 N11 placed at right angles to one another. The coils are preferably wound on a frame O of insulating material and their ends are connected to the fixed terminals T T T1 T1.

The generator G is a representative of that class of alternating current machines in which a stationary induced current is employed. That shown consists of a revolving permanent or electro-magnet A and four independent stationary magnets P P1 wound with coils. The diametrically opposite coils being connected in series and having their ends secured to the terminals t t t1 t1. From these terminals the currents are led to the terminals of the motor, as shown in the drawing.

The mode of operation is substantially the same as in the previous cases, the currents traversing the coils of the motor having the effect to turn the disk D. This mode of carrying out the invention has the advantage of dispensing with the sliding contacts in the system.

In the forms of motor above described, only one of the elements, the armature or the field magnet is provided with energizing coils. It remains then to show how both elements may be wound with coils. Reference is therefore had to Figures 17 and 18.

Figure 17 is an end view of such a motor with the diagram of connections. Figure 18 is a view of the generator with the field magnets in section. In Figure 17 the field magnet of the motor consists of a ring R, preferably of thin insulated iron sheets or bands with eight pole pieces G1 and corresponding recesses in which four pairs of coils V are wound. The diametrically opposite pairs of coils are connected in series and the free ends connected to four terminals W. The rule to be followed in connection being the same as hereinbefore explained.

An armature D with two coils E E1 at right angles to each other, is mounted to rotate inside of the field magnet R. The ends of the armature coils are connected to two pairs of contact rings d d d1 d1.

The generator for this motor may be of any suitable kind to produce currents of the desired character. In the present instance it consists of a field magnet N S and an armature A with two coils at right angles, the ends of which are connected to four contact rings b b b1 b1 carried by its shaft.

The circuit connections are established between the rings on the generator shaft and those on the motor shaft by collecting brushes and wires as previously explained. In order to properly energize the field magnet of the motor however, the connections are so made with the armature coils by wires leading thereto, that while the points of greatest attraction or greatest density of magnetic lines of force upon the armature are shifted in one direction, those upon the field magnet are made to progress in an opposite direction. In other respects the operation is identically the same as in the other cases described. This arrangement results in an increased speed of rotation.

In Figure 17, for example, the terminals of each set of field coils are connected with the wires to the armature coils in such way that the field coils will maintain opposite poles in advance of the poles of the armature.

In the drawings the field coils are in shunts to the armature, but they may be in series or in independent circuits.

It is obvious that the same principle may be applied to the various typical forms of motor hereinbefore described.

Figure 19 is a diagram similar to figure 9, illustrating a modification in the motor. In this figure the various parts are the same as in figure 9, except that the armature core of the motor is wound with two coils at right angles to each other, the core being a cylinder or disk. The two coils form independent closed circuits. This arrangement of closed induced circuits will be found to give very efficient results.

When a motor thus constructed is not loaded, but running free, the rotation of the armature is practically synchronous with the rotation of the poles in the field, and under these circumstances very little current is perceptible in the coils C C1, but if a load is added the speed tends to diminish and the currents in the coil are augmented so that the rotary effect is increased proportionately.

This principle of construction is obviously capable of many modified applications, most of which follow as a matter of course from the constructions described ; for instance, the armature or induced coils or those in which the currents are set up by induction, may be held stationary and the alternating currents from the generator conducted through the rotating inducing or field coils by means of suitable sliding contacts. It is also apparent that the induced coils may be movable and the magnetic parts of the motor stationary.

An advantage and a characteristic feature of motors constructed and operated in accordance with this plan, is their capability of almost instantaneous reversal by the reversal of one of the energizing currents from the generator.

This will be understood from a consideration of the working conditions. Assuming the armature to be rotating in a certain direction following the movement of the shifting poles, then let the direction of the shifting be reversed which may be done by reversing the connections of one of the two energizing circuits. If it be borne in mind that in a dynamo-electric machine the energy developed is very nearly proportionate to the cube of the speed it is evident that at such moment an extraordinary power is brought to play in reversing the motor. In addition to this the resistance of the motor is very greatly reduced at the moment of reversal so that a much greater amount of current passes through the energizing circuits.

The phenomenon alluded to, viz.: the variation of the resistance of the motor, apparently like that in ordinary motors, is probably attributable to the variation in the amount of self-induction in the primary or energizing circuit.

In lieu of the field magnets for the motors shown in the drawings soft iron field magnets excited by a continuous current may be used.

This plan is a very advantageous one, but it is characteristic of a motor so operated that if the field magnet be strongly energized by its coils and the circuits through the armature coils closed, assuming the generator to be running at a certain speed, the motor will not start but if the field be but slightly energized or in general in such condition that the magnetic influence of the armature preponderates in determining its magnetic condition, the motor will start and, with sufficient current, will reach its normal or maximum speed. For this reason it is desirable to keep, at the start and until the motor has attained its normal speed or nearly so, the field circuit open, or to permit but little current to pass through it.

Another characteristic of this form of motor is, that its direction of rotation is not reversed by reversing the direction of the current through its field coils, for the direction of rotation depends, not upon the polarity of the field, but upon the direction in which the poles of the armature are shifted. To reverse the motor the connections of either of the energizing circuits must be reversed.

It will be found if the fields of both the generator and motor be strongly energized that starting the generator starts the motor, and that the speed of the motor is increased in synchronism with the generator.

Motors constructed and operated upon this principle maintain almost absolutely the same speed for all loads within their normal working limits, and in practice it will be observed that if the motor is suddenly overloaded to such an extent as to check its speed, the speed of the generator, if its motive power be not too great is diminished synchronously with that of the motor. These qualities render this particular form of motor very useful under certain conditions.

With this description of the nature of the invention and of some of the various ways in which it is carried into effect, attention is called to certain characteristics which the applications of the invention possess, and the advantages which it offers.

In this motor, considering for convenience, that represented in Figure 9, it will be observed that since the disk D has a tendency to follow continuously the points of greatest attraction, and since these points are shifted around the ring once for each revolution of the armature of the generator, it follows that the movements of the disk D will be synchronous with that of the armature A. This feature will be found to exist in all other forms in which one revolution of the armature of the generator produces a shifting of the poles of the motor through three hundred and sixty degrees.

In the particular modification shown in Figure 15 or in others constructed on a similar plan, the number of alternating impulses resulting from one revolution of the generator armature is double as compared with the preceding cases, and the polarities in the motor are shifted around twice by one revolution of the generator armature. The speed of the motor will, therefore, be twice that of the generator.

The same result is evidently obtained by such a disposition as that shown in figure 17 where the poles of both elements are shifted in opposite directions.

Again, considering the apparatus illustrated by figure 9, as typical of the invention, it is obvious that since the attractive effect upon the disk D is greatest when the disk is in its proper relative position to the poles developed in the ring R, that is to say, when its ends or poles immediately follow those of the ring, the speed of the motor for all loads within the normal working limits of the motor will be practically constant.

It is clearly apparent that the speed can never exceed the arbitrary limit as determined by the generator, and also that within certain limits, at least, the speed of the motor will be independent of the strength of the current.

It will now be more readily seen from the above description how far the requirements of a practical system of electrical transmission of power are realized by this invention. It secures:

First, a uniform speed under all loads within the normal working limits of the motor without the use of any auxiliary regulator.

Second, synchronism between the motor and generator.

Third, greater efficiency by the more direct application of the current, no commutating devices being required on either the motor or generator.

Fourth, cheapness and simplicity of mechanical construction.

Fifth, the capability of easy management and control.

Sixth, diminution of danger from injury to persons and apparatus.

These motors may be run in series multiple arc or multiple series under conditions well understood by those skilled in the art.

The means or devices for carrying out the principle of this invention may be varied to a far greater extent than has been indicated herein, but the invention includes in general, motors containing two or more independent circuits through which, the operating currents are directed in the manner described. By “independent” it is not implied that the circuits are necessarily isolated from one another for in some instances there might be electrical connections between them to regulate or modify the action of the motor without necessarily producing a new or different action.

It is not new to produce the rotation of a motor by intermittently shifting the poles of one of its elements. This has been done by passing through independent energizing coils on one of the elements the current from a battery or other source of direct or continuous currents, reversing such currents by suitable mechanical appliances so that they are directed through the coils in alternately opposite directions. In such cases however, the potential of the energizing current remains the same, their direction only being changed. According to the present invention, on the other hand, true alternating currents are employed and the invention consists in the mode or method of an apparatus for utilizing such currents.

The difference between the two plans and the advantages of this one are obvious. By producing an alternating current each impulse of which involves a rise and fall of potential, the exact conditions of the generator are reproduced in the motor, and by such currents and the consequent productions of resultant poles, the progression of the poles will be continuous and not intermittent. In addition to this, the practical difficulty of interrupting or reversing a current of any considerable strength is such that none of the devices at present known could be made to economically or practically effect the transmission of power by reversing, in the manner described, a continuous or direct current.

In so far, then, as the plan of acting upon one element of the motor is concerned, my invention involves the use of an alternating as distinguished from a reversed current, or a current which while continuous and direct is shifted from coil to coil by any form of commutator, reverser or interruptor. With regard to that part of the invention which consists in acting upon both elements of the motor simultaneously, the use of either alternating or reversed currents is within the scope of the invention, although the use of reversed currents is not regarded as of much practical importance.

Having now particularly described and ascertained the nature of the said invention and in what manner the same is to be performed as communicated to me by my foreign correspondent I declare that what I claim is:-

- The method herein described of electrically transmitting power which consists in producing a continuously progressive movement of the polarities of either or both elements (the armature or field magnet or magnets) of a motor by developing alternating currents in independent circuits including the magnetizing coils of either or both elements, as herein set forth.

- The combination with a motor containing separate or independent circuits on the armature or field or both, of an alternating current generator containing induced circuits connected independently to corresponding circuits in the motor, whereby a rotation of the generator produces a progressive shifting of the poles of the motor, as herein described.

- In a system for the electrical transmission of power, the combination of a motor provided with two or more independent magnetizing coils corresponding to the motor coils and circuits connecting directly the motor and generator coils in such order that the currents developed by the generator will be passed through the corresponding motor coils and thereby produce a progressive shifting of the poles of the motor, as herein set forth.

- The combination with the motor having an annular or ring shaped field and a cylindrical or equivalent armature, and independent coils on the field or armature or both, of an alternating current generator having correspondingly independent coils and circuits including the generator coils and corresponding motor coils in such manner that the rotation of the generator causes a progressive shifting of the poles of the motor in the manner set forth.

- In a system for the electrical transmission of power, the combination of the following instrumentalities, to wit: A motor composed of a disk or its equivalent, mounted within a ring or annular field which is provided with magnetizing coils connected in diametrically opposite pairs or groups to independent terminals, a generator having induced coils or groups of coils equal in number to the pairs or groups of motor coils and circuits connecting the terminals of said coils to the terminals of the motor respectively and in such order that the rotation of the generator and the consequent production of alternating currents in the respective circuits produces a progressive movement of the polarities of the motor, as hereinbefore described.

- The method herein described of operating electro-magnetic motors which consists in producing a progressive shifting of the poles of its armature by an alternating current and energizing its field magnets by a continuous current as set forth.

- The combination with a motor containing independent inducing or energizing circuits and closed induced circuits, of an alternating current generator having induced or generating circuits corresponding to and connected with the energizing circuits of the motor as set forth.

- An electro-magnetic motor having its field magnets wound with independent coils and its armature with independent closed coils in combination with a source of alternating currents connected to the field coils and capable of progressively shifting the poles of the field magnet, as set forth.

Dated this 1st day of May 1888.

Haseltine, Lake & Co.,

45, Southampton Buildings, London, W.C.,

Agents for the Applicant.