TCBA Volume 7 - Issue 1

Page 7 of 18

211 Vacuum Tube Tesla Coil

by

John C. Wiesner

Wiesner Radio & Electronics

Albany, NY

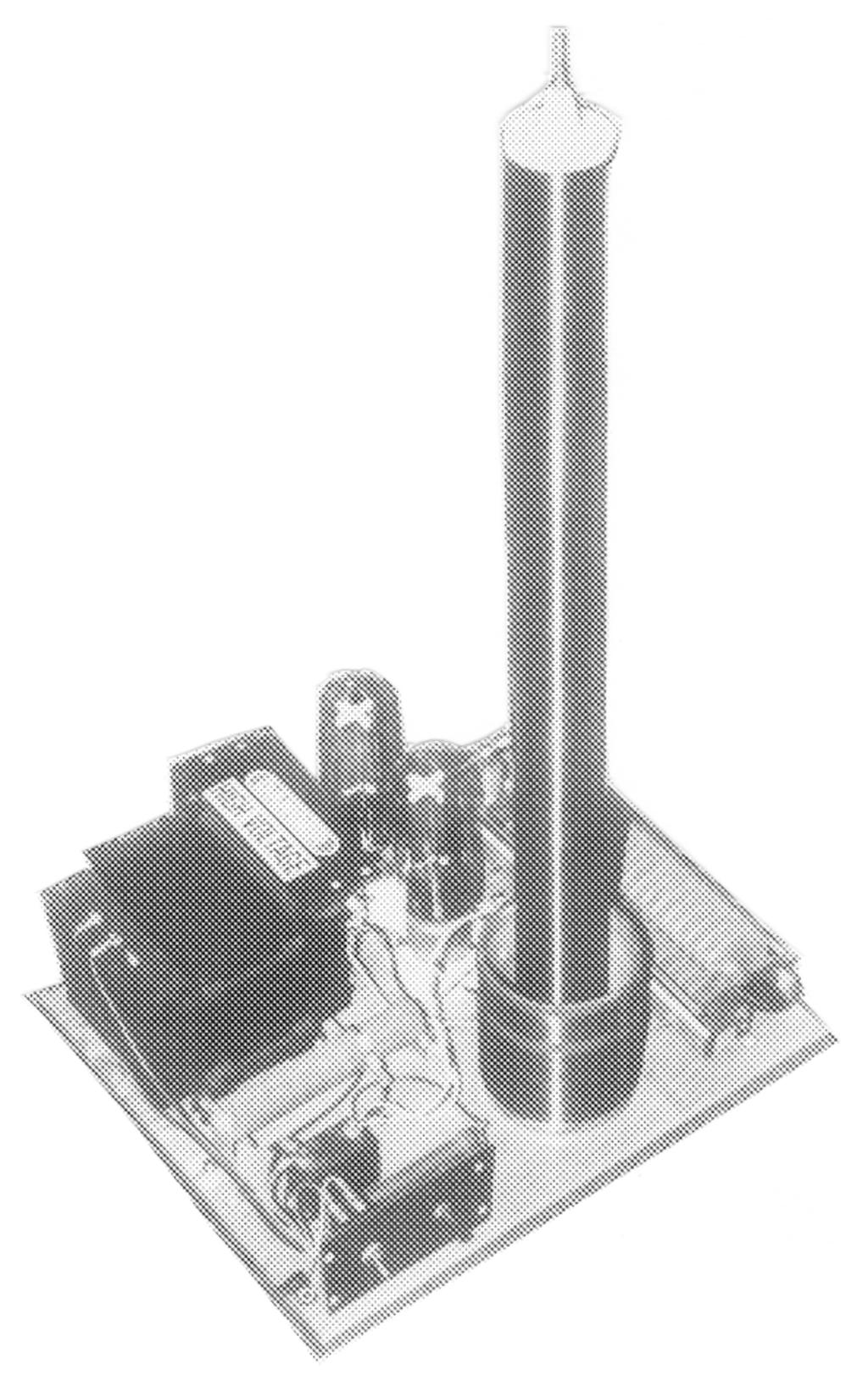

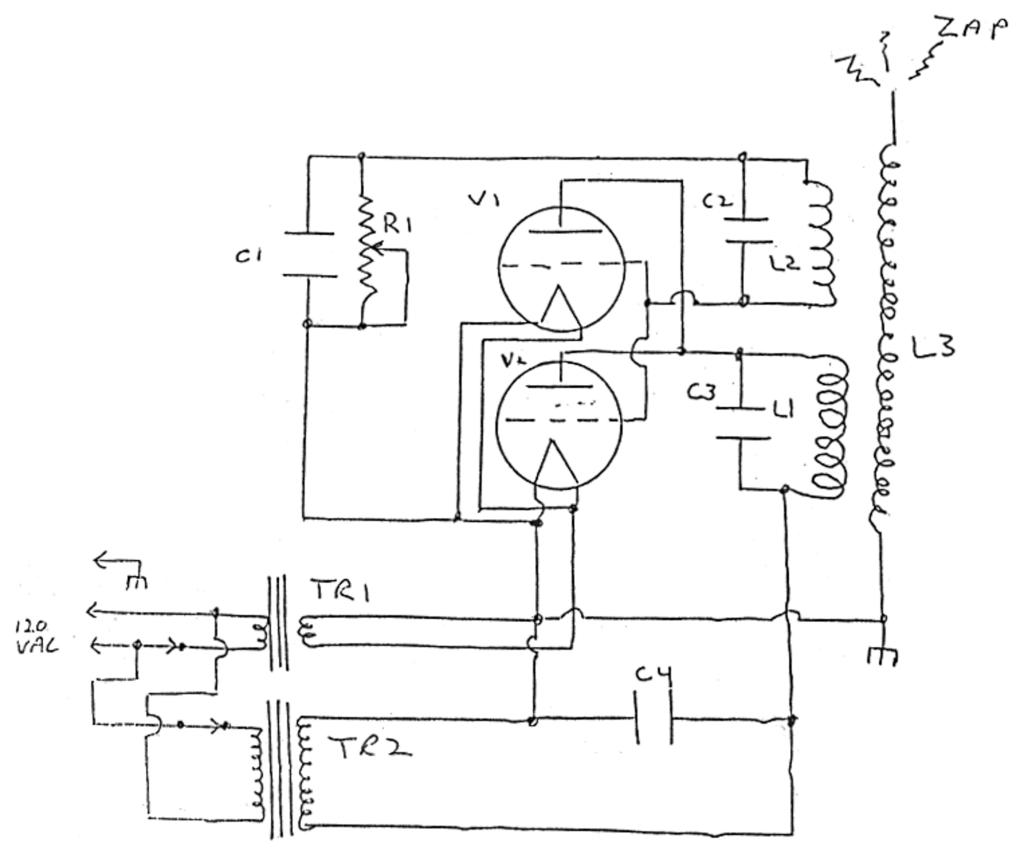

The 211 tube Tesla coil is capable of discharges of 12" in length. It is powered by an old diathermy transformer providing the 10 volts for the filament and 1650 volts for the plate supply. The primary coil is wound on a shellacked cardboard form. The secondary wound on PVC plastic pipe with #32 wire. The ends are fitted with plywood plugs and cemented with GE silicone seal.

The Tesla coil may have a high and low power setting just by switching grid bias resistors. A grid resistor of 15-20K is suitable for the low power position. The high power setting uses a 1.5-5K resistor in the circuit. You will notice a tweak in the low power position.

To get the maximum out of the coil, the capacitor in the plate circuit should be varied until the longest 'discharge is obtained. The variable capacitor is optional. It is hooked into the circuit in parallel with the 500 pF cap across the grid coil. The capacitors I used are surplus mica transmitting units of from 3-6 KV.

Other tubes may be substituted for the 211. Tubes such as VT-4C, 810, or 203A work well.

I found that a plywood base 14X18" is a suitable size. Also, it is easier to lift if 1/2" wood cleats are glued underneath

Parts Description

- C1 - .004 mica 2KV

- C2 - 500 pF mica or doorknob cap, 3KV

- C3 - .002 6KV transmitting mica

- C4 - .002 6KV

- R1 - 5K 50 watt ADJ. wirewound resistor

- TR1- 10V 10A filament transformer

- TR2- 1550-1650V, 300 Ma plate transformer

- V1 + V2 #211 transmitting tubes (or similar tubes mentioned in text)

- L1 & L2 are wound on 5 1/4X4 1/2" OC form (see text)

- L1 - 18 turns of double #16 AWG wound in parallel and spaced with string. Start winding 3/8" from bottom of form, finish 3" from bottom of form.

- L2 - 18 turns of #20 AWG. Start winding 1/8" from top of form. Space with string or use covered wire to give a total width of winding 1 1/16"

- Use plastic screws to secure wire to form.

- L3 - PVC form 2 1/2" OD and 30" high with #32 AWG.