TCBA Volume 8 - Issue 1

Page 10 of 18

Tesla Coils Resurrected

Spectacular High Frequency Experiments

Made with Aid of Junked Ignition Coil

By

Kendall Ford

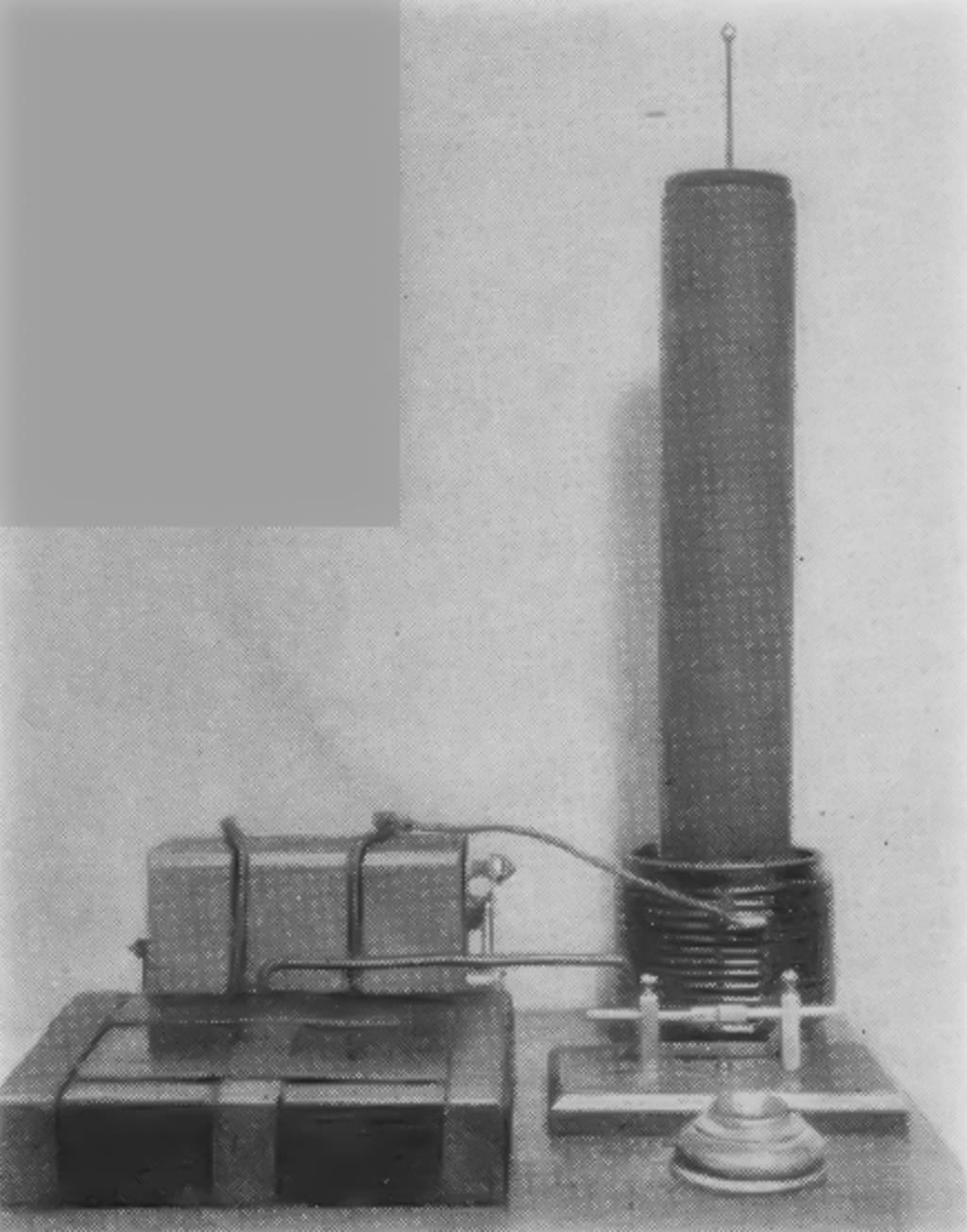

Here is a high-frequency outfit capable of giving a good 3-in. spark and providing an endless number of weird and interesting experiments, yet it can be built in a few hours time and almost entirely from salvaged materials.

Obtain a mailing tube approximately 2 in. in diameter and 12 in. long. Cut two circular blocks of 1/2 in. wood to fit into the ends of the tube, and bore a 1/4-in. hole through the center of one of the blocks. Glue a short piece of 1/4-in. round wooden rod in the center of the latter block and allow it to extend 1/2 in. from the surface as a dowel. Glue one block in each end of the tube, shellac the tube, and allow it to dry.

If a mailing tube is not available, a satisfactory substitute may be made by making a form as shown at Fig. 1, wrapping it with several layers of thin cardboard, and securing the end with glue. No nails or screws should be used in the construction of the high-frequency coil.

Wind the cardboard tube to within 1/4 in. of each end with No. 30 double cotton-covered wire, which will require approximately 350 ft. or a fraction over 1/8 lb. Insert a 1/8-in. brass rod, 4 in. long, in the top end of the coil form, and solder one end of the coil to it. Fasten a small metal ball to the upper end of the rod.

For the primary coil, obtain a cardboard tube 3 in. long and from 3 to 4 in. in diameter. A section of a salt or oatmeal box makes a good form. Cut a circular block of wood to fit into one end, drill a 1/4-in. hole through the center, and glue in place. Wind the form with ten turns of No. 14 rubber-covered wire from which the insulation has been removed for a space of 1/2 in. on each turn, as shown in Fig. 2. The wire is first wound on the form, the spaces to be bared are marked with a sharp knife, the wire is removed, and the insulation cut away. Secure the wire by removing the insulation from the end and passing the wire through a small hole in the cardboard form. Insert the extended end of the first-made or secondary coil into the same hole in the bottom of the primary coil, and glue in place. Then solder the lower end of the secondary coil to the lower end of the primary coil.

For the condenser obtain fourteen pieces of glass, 5 by 7 in. Old photograph plates from which the emulsion has been removed are excellent, but any scrap pieces of glass will do. Cut thirteen pieces of brass, copper, or tinfoil to the size and shape shown in Fig. 3. Drill holes in the tabs at the end of the sheet for connecting screws as shown. In stacking the condenser, place a sheet of glass on a flat surface, then a sheet of foil on the glass, another sheet of glass, then a sheet of foil with the tab at the opposite end. Continue until the condenser is assembled as in Fig. 3. The foil should be placed on the glass so that there is a margin of 1/2 in. all the way around. Bind the condenser together with friction tape.

POPULAR SCIENCE MONTHLY - FERUARY 1935